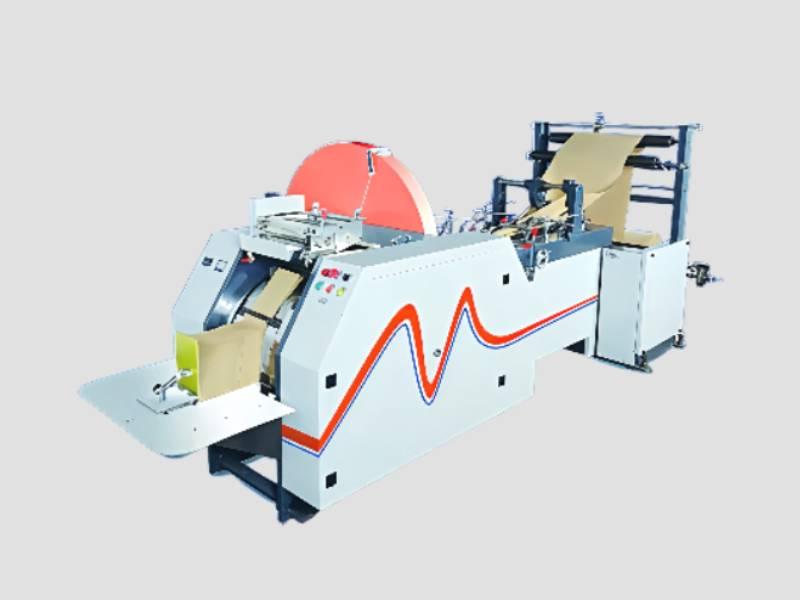

Carmel offers a comprehensive range of blown film extrusion lines designed to produce high-quality polyethylene films for a wide variety of industrial and consumer applications. These lines are engineered to deliver consistent film thickness, excellent clarity, strong sealing properties, and reliable performance across both lightweight and heavy-duty packaging needs.Our blown film lines support multiple end-use products including grocery carry bags, T-shirt bags, garbage bags, shipping and courier packaging films, food packaging films, mulch films, grow bags, and other flexible packaging or agricultural films. Depending on the application, customers can select the most suitable resin type from HM, HDPE, LDPE, or LLDPE, either as single raw materials or in blends to achieve specific mechanical or optical properties.Carmel provides both compact monolayer models for customers who need efficient, space-saving production of standard films, and advanced custom-built co-extrusion multilayer lines for higher-performance packaging. Monolayer systems are ideal for simple bag and general-purpose film manufacturing, while multilayer co-extrusion machines enable the production of films with improved strength, stiffness, barrier performance, printability, and sealing characteristics—perfect for premium food, logistics, and specialty packaging.

We can able to supply allover INDIA areas like chennai, madurai, theni, tirunelveli, thoothukudi, virudhunagar, sivakasi, karaikudi, karaikal, pondicherry, tiruchirapalli, salem, coimbatore, karur, krishnagiri, tiruvallur, chengalpattu, kanchipuram, nellore, kadapa, tirupati, vishakapattinam, hyderabad, banglore, mysuru, goa, mumbai, delhi, kolkata, chandigarh, odissa, nagaland, amristar, rajasthan, maharastra.