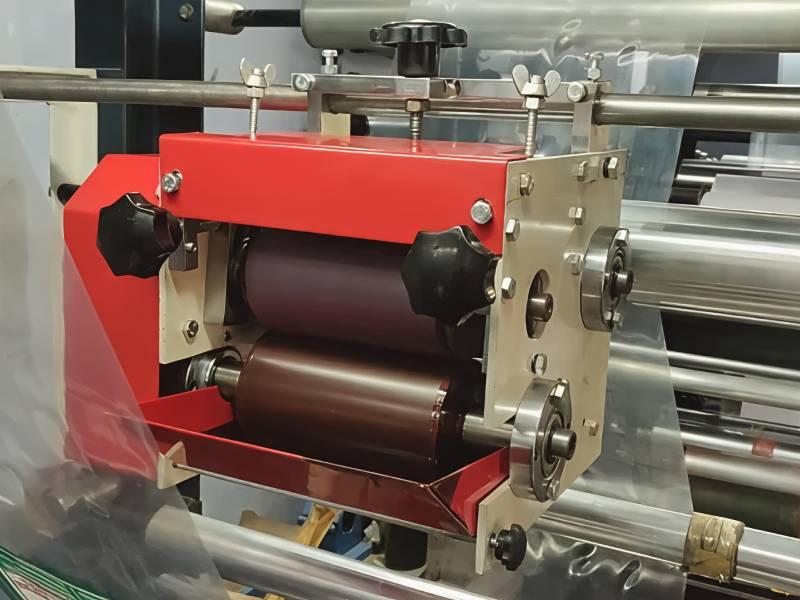

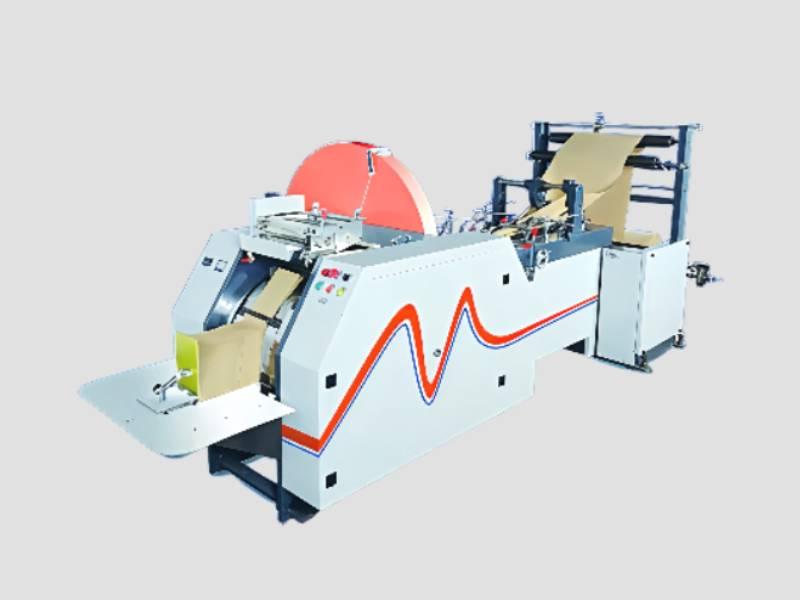

A rotogravure printing machine is a high-speed rotary printing system that produces premium, consistent images on flexible packaging materials. It works on the gravure principle, where the required design is engraved as tiny recessed cells on a metal cylinder. During operation, the cylinder rotates through ink, a doctor blade removes excess ink from the surface, and the ink trapped in the engraved cells transfers onto the substrate under pressure from an impression roller. The machine has a separate printing unit for each color—typically arranged in CMYK (Cyan, Magenta, Yellow, and Key/Black)—and can be built with additional units when special shades or extra colors are needed. Because it delivers excellent color depth, smooth tonal gradients, and accurate registration at high production speeds, rotogravure printing is widely used for long-run printing of films, paper, foils, laminates, and other packaging webs.

We can able to supply allover INDIA areas like chennai, madurai, theni, tirunelveli, thoothukudi, virudhunagar, sivakasi, karaikudi, karaikal, pondicherry, tiruchirapalli, salem, coimbatore, karur, krishnagiri, tiruvallur, chengalpattu, kanchipuram, nellore, kadapa, tirupati, vishakapattinam, hyderabad, banglore, mysuru, goa, mumbai, delhi, kolkata, chandigarh, odissa, nagaland, amristar, rajasthan, maharastra.