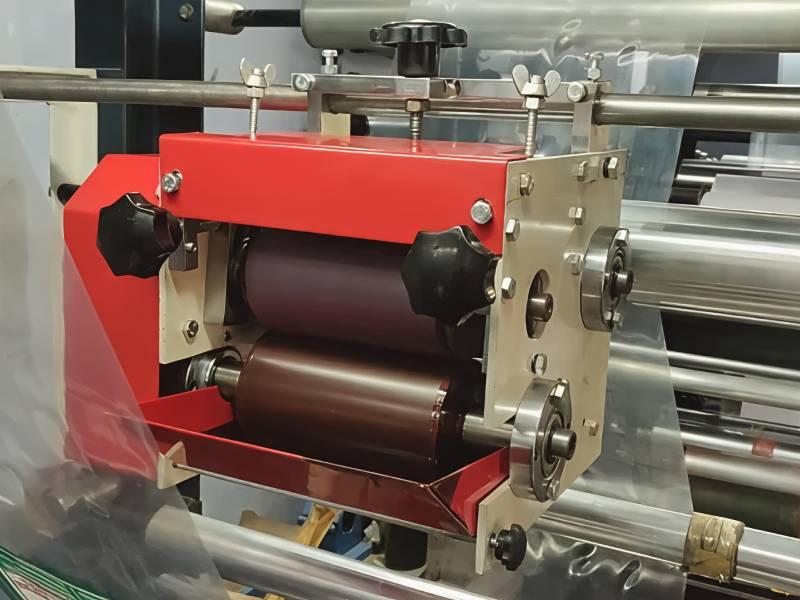

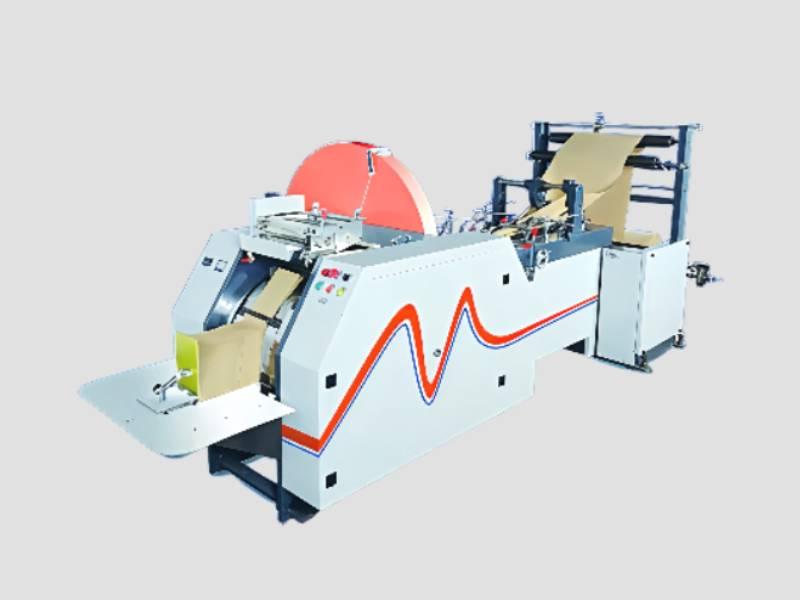

Carmel’s Lamination Machine is built to handle a broad spectrum of flexible packaging lamination jobs, including aluminium foil, paper, plastic films, and similar substrates, delivering strong, uniform bonding for premium laminated output. The machine is perfectly integrated with new-generation electronic systems to ensure optimum performance, stable run quality, and high productivity across different material combinations. Laminated products produced on this machine provide reliable resistance against vapors and general gases, making them suitable for protective and shelf-life sensitive packaging. It is ideal for processing various polycell bags and laminated bag structures, enhancing them with oil-proof and water-proof properties for tougher, more durable packaging. With 3-speed or 5-speed drive technology, the machine offers flexible production control, while its easy-operation design and optimum energy consumption keep running costs low. Pneumatically operated doctor blade and impression roller systems ensure smooth adhesive application and consistent lamination pressure, and the web chaser supports stable web tracking and alignment for neat, wrinkle-free finishing.

We can able to supply allover INDIA areas like chennai, madurai, theni, tirunelveli, thoothukudi, virudhunagar, sivakasi, karaikudi, karaikal, pondicherry, tiruchirapalli, salem, coimbatore, karur, krishnagiri, tiruvallur, chengalpattu, kanchipuram, nellore, kadapa, tirupati, vishakapattinam, hyderabad, banglore, mysuru, goa, mumbai, delhi, kolkata, chandigarh, odissa, nagaland, amristar, rajasthan, maharastra.