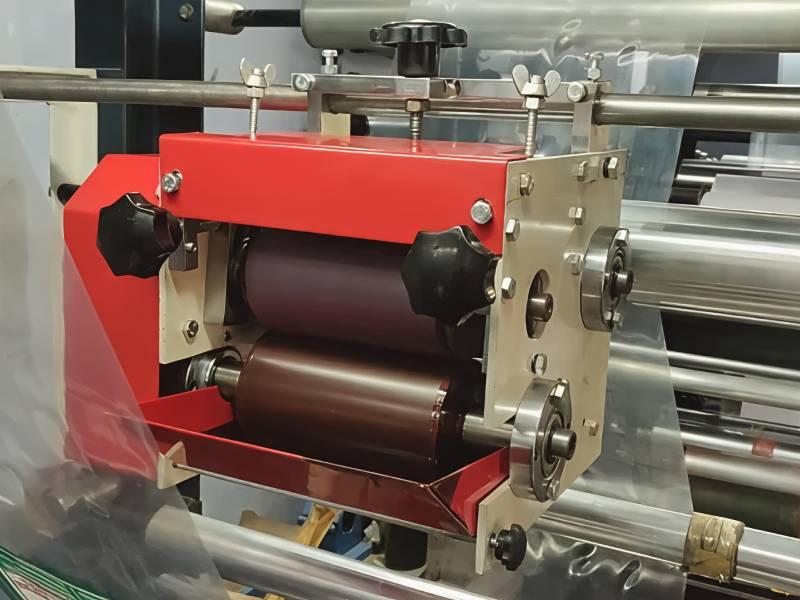

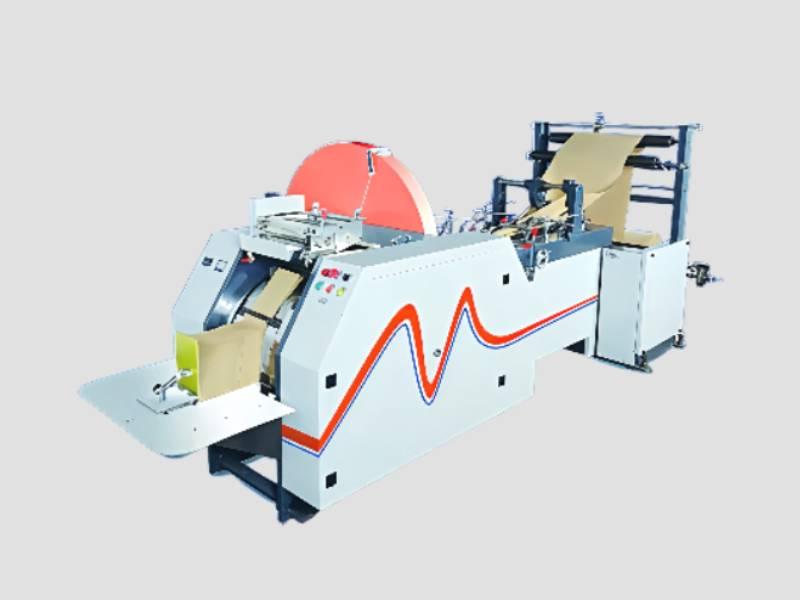

This duplex slitting re-winder is a cantilever, center-winding machine engineered for precision slitting and rewinding of a wide range of flexible materials such as high-tensile films, foil, laminates, paper, BOPP/BDPP, and LLDPE. Built for stable performance and consistent roll quality, it combines robust mechanical construction with a user-friendly layout to ensure easy operation and minimal maintenance over long production cycles. For safe and reliable running, safety interlocks are integrated into every operational sequence, protecting both the operator and the machine during start, stop, and changeover. The system supports both razor blade slitting for thin films and rotary slitting for tougher or thicker webs, offering flexibility across job types. A heavy-duty friction rewind arrangement with multiple bearing supports ensures smooth tension control and tight, uniform rewound rolls, even at higher speeds. Fast changeover capability reduces downtime between jobs, making the machine ideal for converters who need quick setup, repeat accuracy, and efficient finishing of packaging rolls.

We can able to supply allover INDIA areas like chennai, madurai, theni, tirunelveli, thoothukudi, virudhunagar, sivakasi, karaikudi, karaikal, pondicherry, tiruchirapalli, salem, coimbatore, karur, krishnagiri, tiruvallur, chengalpattu, kanchipuram, nellore, kadapa, tirupati, vishakapattinam, hyderabad, banglore, mysuru, goa, mumbai, delhi, kolkata, chandigarh, odissa, nagaland, amristar, rajasthan, maharastra.