Key Attributes

Industry-specific Attributes

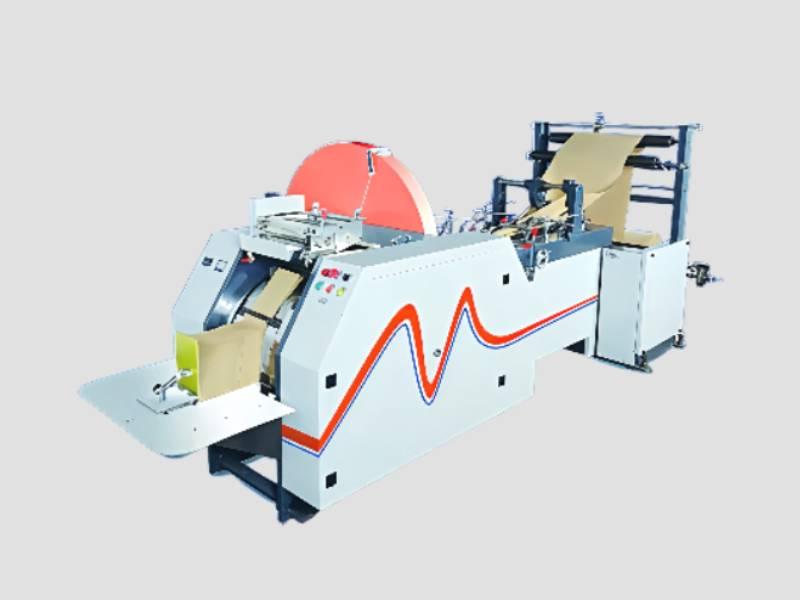

- Product Type Flexography (Flexo) Printing Machine

- Printing Process Flexographic roll-to-roll printing

- Printing Plate Type Flexible photopolymer plates

- Substrates Supported Plastic films, paper, woven fabric, non-woven fabric, and other flexible rolls

- Adjustment System Micrometric adjustment at each printing station

Other Attributes

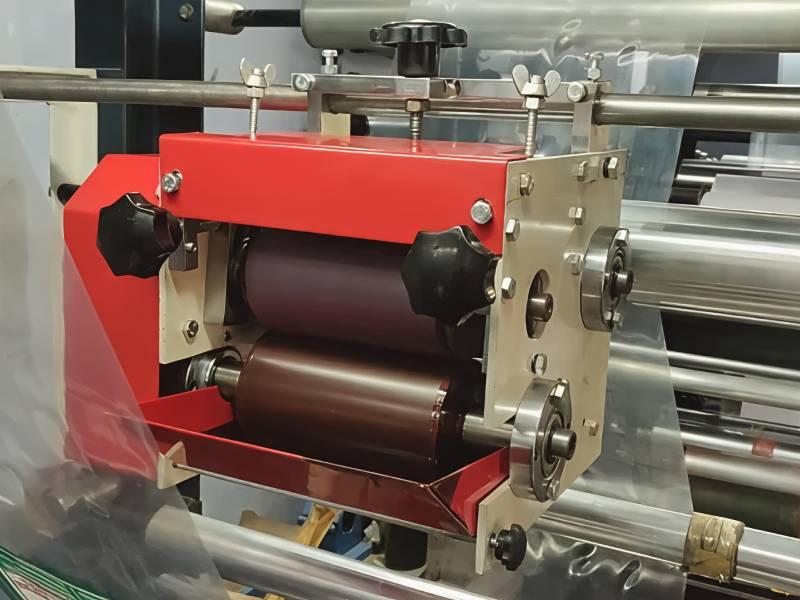

- Anilox-to-Plate Setting Fine premium adjustment from anilox roll to printing cylinder

- Plate-to-Substrate Setting Fine premium adjustment from printing cylinder to final product

- Registration Quality Perfect registration control

- Impression Quality Uniform impression across web width

- Drying System Air drying with high-velocity centrifugal fan