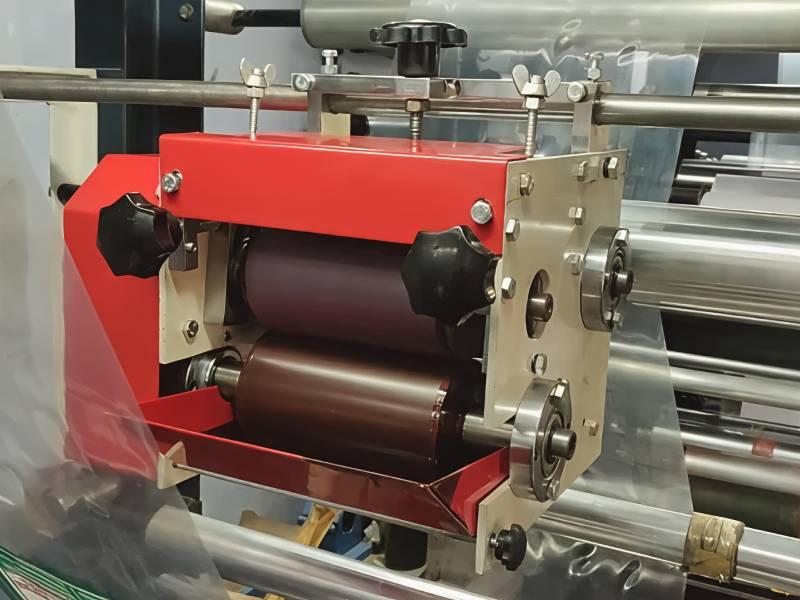

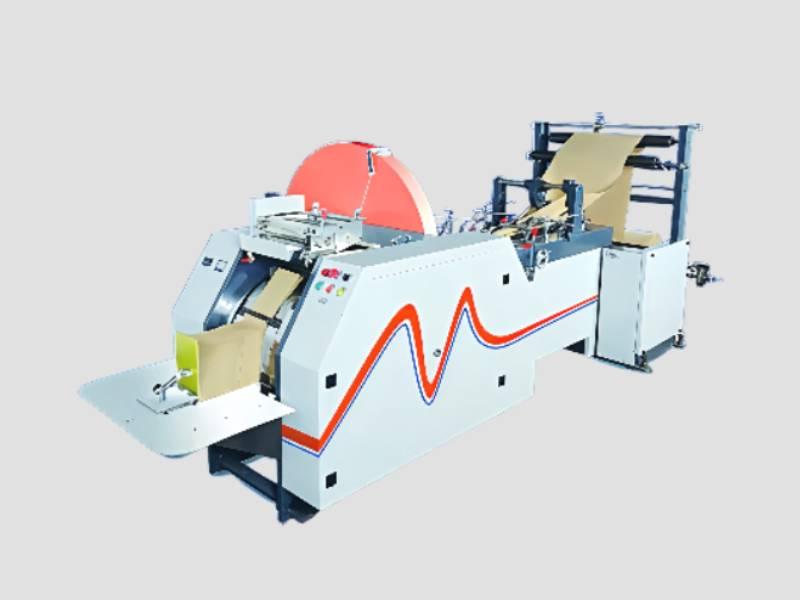

Carmel’s Roll-to-Roll Gusseting Machine is a dedicated converting solution used to create precise side gussets on continuous film rolls for HM (High Molecular Weight Polyethylene), LDPE (Low-Density Polyethylene), and PP (Polypropylene) bags. By forming gussets, the machine increases the bag’s cross-section, allowing it to expand outward during filling and significantly improving the volume the bag can hold. This makes gusseted bags ideal for packing bulkier or higher-capacity products while maintaining neat shape and strength. The machine is engineered for smooth roll-to-roll operation with stable web handling, ensuring uniform folding and consistent gusset formation across the entire roll. Its design emphasizes easy operation and minimal downtime, featuring a simple yet highly accurate gusset-depth adjustment mechanism so operators can quickly set and maintain the required gusset size for different bag formats. Built for reliable performance in high-throughput bag lines, the gusseting machine delivers clean, repeatable results that improve bag functionality and overall packing efficiency.

We can able to supply allover INDIA areas like chennai, madurai, theni, tirunelveli, thoothukudi, virudhunagar, sivakasi, karaikudi, karaikal, pondicherry, tiruchirapalli, salem, coimbatore, karur, krishnagiri, tiruvallur, chengalpattu, kanchipuram, nellore, kadapa, tirupati, vishakapattinam, hyderabad, banglore, mysuru, goa, mumbai, delhi, kolkata, chandigarh, odissa, nagaland, amristar, rajasthan, maharastra.